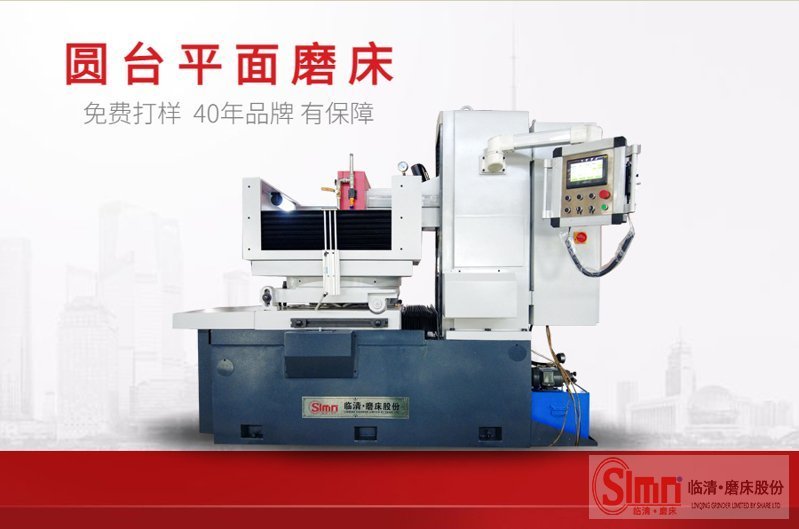

圓(yuan)臺平面磨(mo)床(chuang)(chuang)是一種常用(yong)的金屬加工(gong)(gong)設備,其(qi)工(gong)(gong)作(zuo)原理基于(yu)磨(mo)削(xue)技術。圓(yuan)臺平面磨(mo)床(chuang)(chuang)主(zhu)要(yao)由主(zhu)軸、磨(mo)石、工(gong)(gong)作(zuo)臺和傳動(dong)裝置組(zu)成(cheng)。當圓(yuan)臺平面磨(mo)床(chuang)(chuang)啟動(dong)磨(mo)床(chuang)(chuang)時,主(zhu)軸開始旋轉,并且通過傳動(dong)裝置將(jiang)轉動(dong)動(dong)力(li)傳遞(di)到工(gong)(gong)作(zuo)臺。磨(mo)石安裝在主(zhu)軸上,其(qi)表面覆蓋(gai)著磨(mo)削(xue)顆粒,用(yong)于(yu)對工(gong)(gong)件進行磨(mo)削(xue)。

工(gong)(gong)作過程(cheng)中,操作員(yuan)(yuan)將需要加工(gong)(gong)的工(gong)(gong)件(jian)放置在工(gong)(gong)作臺上(shang),并通(tong)過調(diao)整工(gong)(gong)作臺的位置來確保工(gong)(gong)件(jian)與磨石之(zhi)間(jian)的適當(dang)接觸。當(dang)主(zhu)軸旋(xuan)轉(zhuan)時,磨石開始與工(gong)(gong)件(jian)表面接觸,并以(yi)(yi)(yi)高(gao)(gao)速旋(xuan)轉(zhuan)的方(fang)式對其進(jin)行磨削。通(tong)過調(diao)整工(gong)(gong)作臺的高(gao)(gao)度(du)和角度(du),操作員(yuan)(yuan)可以(yi)(yi)(yi)控制磨削的深度(du)和角度(du),以(yi)(yi)(yi)獲(huo)得所需的加工(gong)(gong)效果。

圓(yuan)臺平(ping)面磨(mo)床的(de)工(gong)作原理(li)基于磨(mo)石(shi)的(de)摩擦(ca)(ca)和磨(mo)削(xue)作用。磨(mo)石(shi)的(de)表面具有磨(mo)削(xue)顆(ke)(ke)粒(li),當磨(mo)石(shi)與工(gong)件表面接(jie)觸時,這些(xie)顆(ke)(ke)粒(li)會在(zai)兩者之間形(xing)成摩擦(ca)(ca)力,從而(er)使工(gong)件表面的(de)金屬顆(ke)(ke)粒(li)脫落。這種脫落的(de)金屬顆(ke)(ke)粒(li)將隨著(zhu)磨(mo)石(shi)的(de)旋轉(zhuan)被帶走,同時新(xin)的(de)磨(mo)削(xue)顆(ke)(ke)粒(li)也會被釋放(fang)出來,以保(bao)持磨(mo)削(xue)的(de)連續(xu)進(jin)行。

圓臺平面(mian)磨(mo)床廣泛應用(yong)于金屬(shu)加(jia)工(gong)領域,特別(bie)是用(yong)于對(dui)平面(mian)、圓臺、倒角和斜面(mian)等各種形(xing)狀的(de)工(gong)件進行精密加(jia)工(gong)。該設備的(de)工(gong)作原理簡單易懂(dong),操作靈活方便,能夠提供高精度和高表面(mian)質量的(de)加(jia)工(gong)效果。此外,磨(mo)床還可以通過更換不(bu)同(tong)規(gui)格(ge)和磨(mo)削(xue)顆粒的(de)磨(mo)石來滿足不(bu)同(tong)加(jia)工(gong)要求。

圓臺平面(mian)磨(mo)床(chuang)的工(gong)(gong)作原理(li)是基于磨(mo)削(xue)技術,通過磨(mo)石與工(gong)(gong)件表面(mian)的摩擦和磨(mo)削(xue)作用,實現(xian)對(dui)工(gong)(gong)件的精(jing)密加工(gong)(gong)。它(ta)在金屬(shu)加工(gong)(gong)領域(yu)中發揮著重(zhong)要(yao)作用,為(wei)各種(zhong)形狀的工(gong)(gong)件提供高(gao)精(jing)度和高(gao)表面(mian)質量的加工(gong)(gong)效果,滿足不同加工(gong)(gong)要(yao)求的應用需求。